Case Study: Handheld Smart Laparoscopy Arm for Minimally Invasive Surgery (MIS)

From Prototype to Global Surgical Use

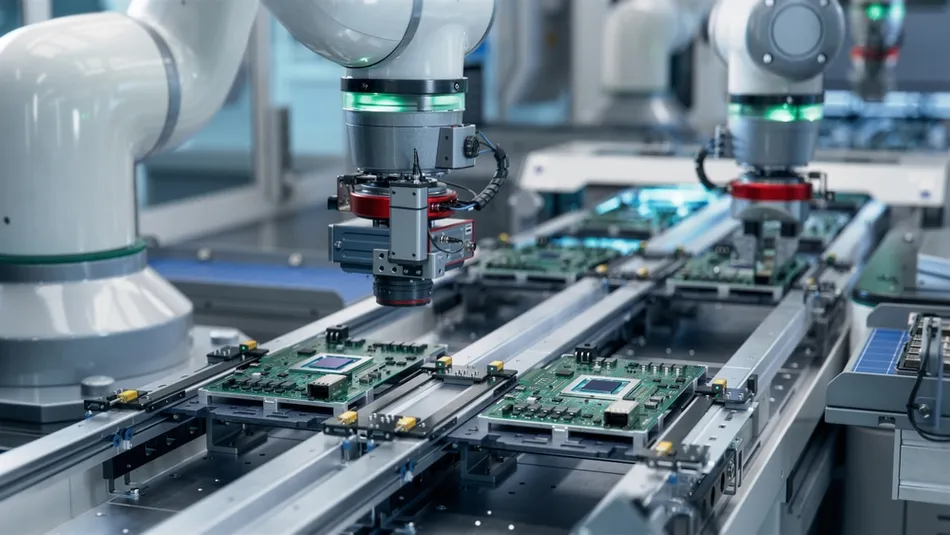

A medical device company developed a handheld smart laparoscopy arm for minimally invasive surgery (MIS) and entrusted us to manufacture it from the early stages through to mass production.

Our Role:

- Early Manufacturing Support: Starting with low-quantity batches of plastic and metal parts, we manufactured components according to the client’s drawings while providing practical feedback to improve performance and manufacturability.

- Collaborative Improvements: Working closely with the client’s engineering team, we helped refine designs, resolve manufacturability challenges, and optimize components to meet demanding medical device standards.

- Certification Readiness: We ensured consistent quality and traceability, supporting the client’s successful achievement of FDA and CE certifications.

- Scaling to Mass Production: Once validated, we transitioned to stable, high-quality mass production for global supply.

Overcoming Technical Challenges

A key challenge in this project was developing a new axis technology that enabled smooth rotation while maintaining flexibility and reliability during surgery. The project also required extremely tight tolerances across complex metal and plastic parts to ensure precise performance in surgical use.

Through close collaboration with the client and leveraging our precision manufacturing capabilities, we overcame these challenges and delivered a robust, unique mechanism that performs reliably in the operating room.

Impact

Today, this handheld smart laparoscopy arm, FDA and CE certified, is used in human surgeries worldwide, enabling surgeons to perform minimally invasive procedures with precision and patient comfort, demonstrating how collaborative manufacturing partnerships can accelerate the advancement of medical technologies.