Case Study: Turnkey Development of a USB Touch Display Featuring SigmaSense’s SDC 300 Controller featuring SigmaTouch AI

Project Overview

SigmaSense, a leading innovator in signal-based touch sensing technologies, engaged MGT Engineering to turnkey design and build a USB touch display platform utilizing SigmaSense’s newly launched SDC 300 capacitive touch controller. The display was intended to serve as a reference platform for OEMs evaluating the SDC 300, requiring robust performance, industrial-grade build quality, and seamless plug-and-play usability.

Objectives

- Rapid prototype-to-production cycle

- Full integration of the SDC 300 with USB interface and driver stack

- Scalable, cost-conscious supply chain and contract manufacturing model

- High-fidelity touch sensitivity across varied environmental conditions

- Premium industrial housing with injection-molded precision

MGT’s Turnkey Execution

MGT led the end-to-end development lifecycle, blending deep technical expertise with agile manufacturing capabilities:

Design & Engineering

- Created schematics for board layout incorporating the SDC 300 controller

- Developed USB interface firmware aligned with SigmaSense’s driver protocols

- Integrated EMI shielding and thermal dissipation structures

Materials & Component Sourcing

- Identified globally available capacitive touch display panels with optimal resolution and transparency

- Secured long-lead components through preferred supply chain partners

- Qualified alternate BOMs for risk mitigation

Housing & Enclosure Development

- Designed custom enclosure using injection-molded ABS/PC blend for durability

- Tooling and mold validation completed within four weeks

- Incorporated vented architecture to support extended operating hours

Prototyping & Testing

- Built initial EVT (Engineering Validation Test) units within 20 business days

- Conducted touch fidelity benchmarking across variable lighting, interference, and glove touch scenarios

- Optimized tuning algorithms for edge detection and multi-touch responsiveness

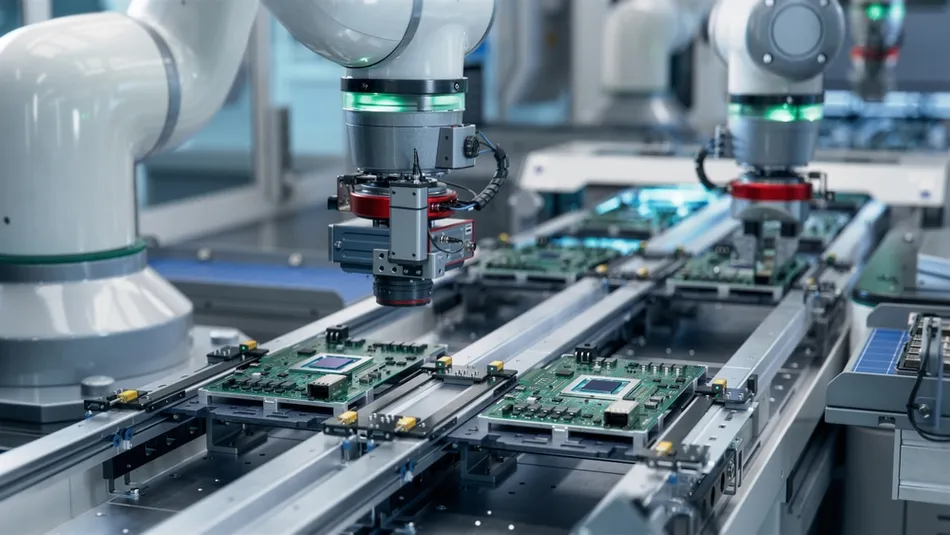

Contract Manufacturing & Assembly

- Transferred BOM, assembly documentation, and firmware stack to selected CM partner

- Oversaw initial production run of 2,500 units with <0.5% failure rate

- Managed logistics to distribution hub with serialized inventory tracking

Results

| Metric | Outcome |

| Development Timeframe | 20 weeks from brief to production |

| Touch Performance | <1mm accuracy |

| Manufacturing Yield | 99.5% |

| Customer Satisfaction | SigmaSense declared platform “market-ready” after PVT review |

Conclusion

SigmaSense’s partnership with MGT delivered a highly integrated, field-ready USB touch display solution that showcased the full power of the SDC 300 controller. The success of the project led to multiple OEM engagements across industrial, medical, and automotive sectors—cementing MGT as a strategic product realization partner in the high-performance sensing space.