Metal Stamping & Formation

Precision Metal Stamping & Forming

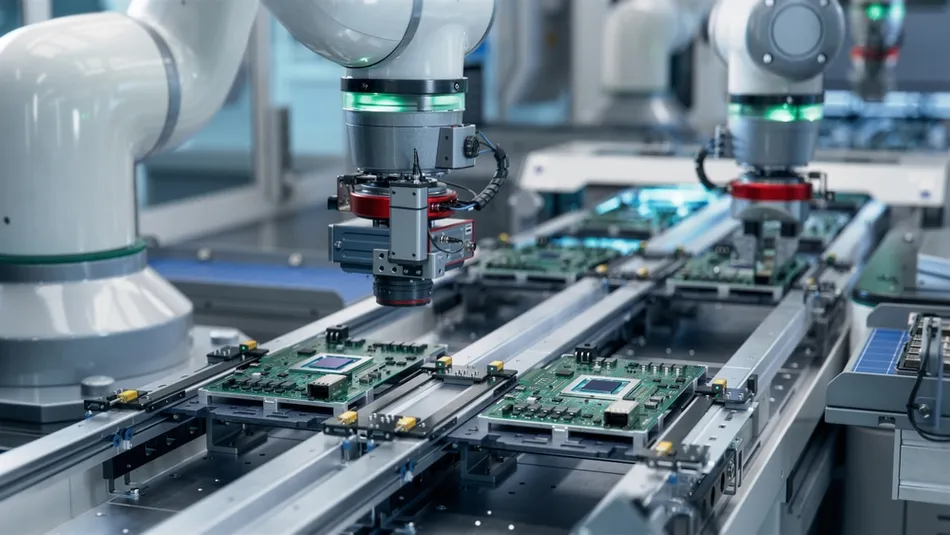

Accelerate Innovation with Precision Machining

Your Gateway to Precision Metal Stamping & Forming in Taiwan

By partnering exclusively with thoroughly vetted, high-performing Taiwanese suppliers, we significantly reduce supply chain disruptions, ensuring consistent quality, reliable delivery, and robust resilience for your critical components.

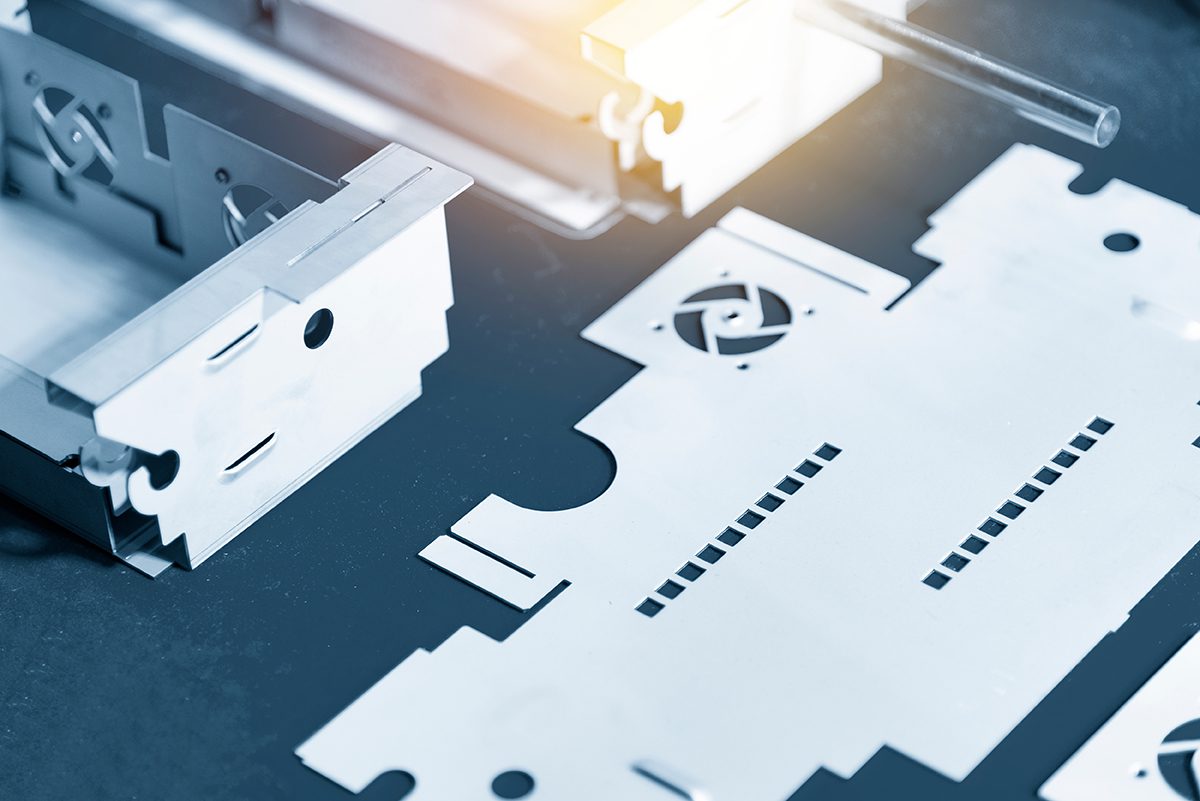

Comprehensive Stamping Processes

Collaboration with experienced Taiwanese die makers ensures the development of robust, long-lasting tooling designed for optimal part quality and production efficiency. Our partners utilize advanced CAD/CAM and simulation software to ensure precise die design and construction.

- Progressive Die Stamping: Ideal for high-volume production of complex parts, ensuring repeatable accuracy and efficiency.

- Deep Draw Stamping: Expertise in producing parts with depths greater than their diameter, maintaining material integrity and consistent wall thickness.

- Compound Die Stamping: Simultaneous cutting and forming operations for precision and speed.

- Fine Blanking: Achieving exceptionally tight tolerances and smooth, sheared edges without secondary finishing operations.

Advanced Forming Techniques: Leveraging hydraulic and mechanical presses, our capabilities include bending, piercing, coining, notching, and other forming operations to create intricate 3D geometries.

Quality Assurance & Inspection: Partnering with ISO certified facilities that employ rigorous in-process and post-production quality control. This includes CMM (Coordinate Measuring Machine) inspections, optical comparators, and statistical process control (SPC) to guarantee adherence to your precise specifications.

Applications: Our metal stamping and forming solutions are critical for sectors including automotive components (brackets, chassis parts), electronics enclosures and internal components, home appliances, medical device housings, telecommunications hardware, and industrial equipment.