SMT & DIP Assembly

Advanced SMT & Through-Hole (THT) PCB Assembly Capabilities

Accelerate Innovation with Precision Machining

Your Gateway to SMT & THT Assembly

MGT Technologies provides comprehensive SMT & THT assembly for enhanced mechanical strength and reliability. They offer precise component insertion and secure soldering. Their expertise extends to mixed technology assembly, combining SMT and THT on the same board for complex, robust designs.

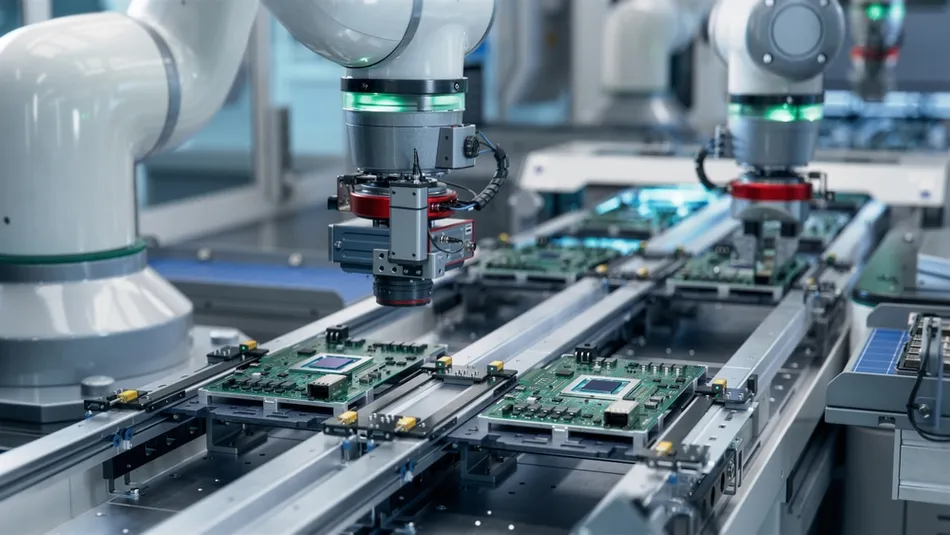

Surface Mount Technology (SMT)

MGT Technologies is highly proficient in SMT assembly, mounting components directly onto the surface of printed circuit boards (PCBs) with precision and efficiency.

- Wide Component Range: From the smallest passive components and fine-pitch flip chips to large-form-factor boards and BGAs (Ball Grid Arrays).

- Advanced Capabilities: High-density SMT, precision die attach, wire bonding, and robust encapsulation techniques with a focus on miniaturization and performance.

- State-of-the-Art Equipment: Utilization of advanced pick-and-place machines with optical positioning systems and precise reflow soldering profiles for consistent quality.

- DFMA Optimization: Employing Design for Manufacturability and Assembly (DFMA) principles to streamline designs for efficient SMT processing, reducing part counts and assembly steps for consistent build quality.

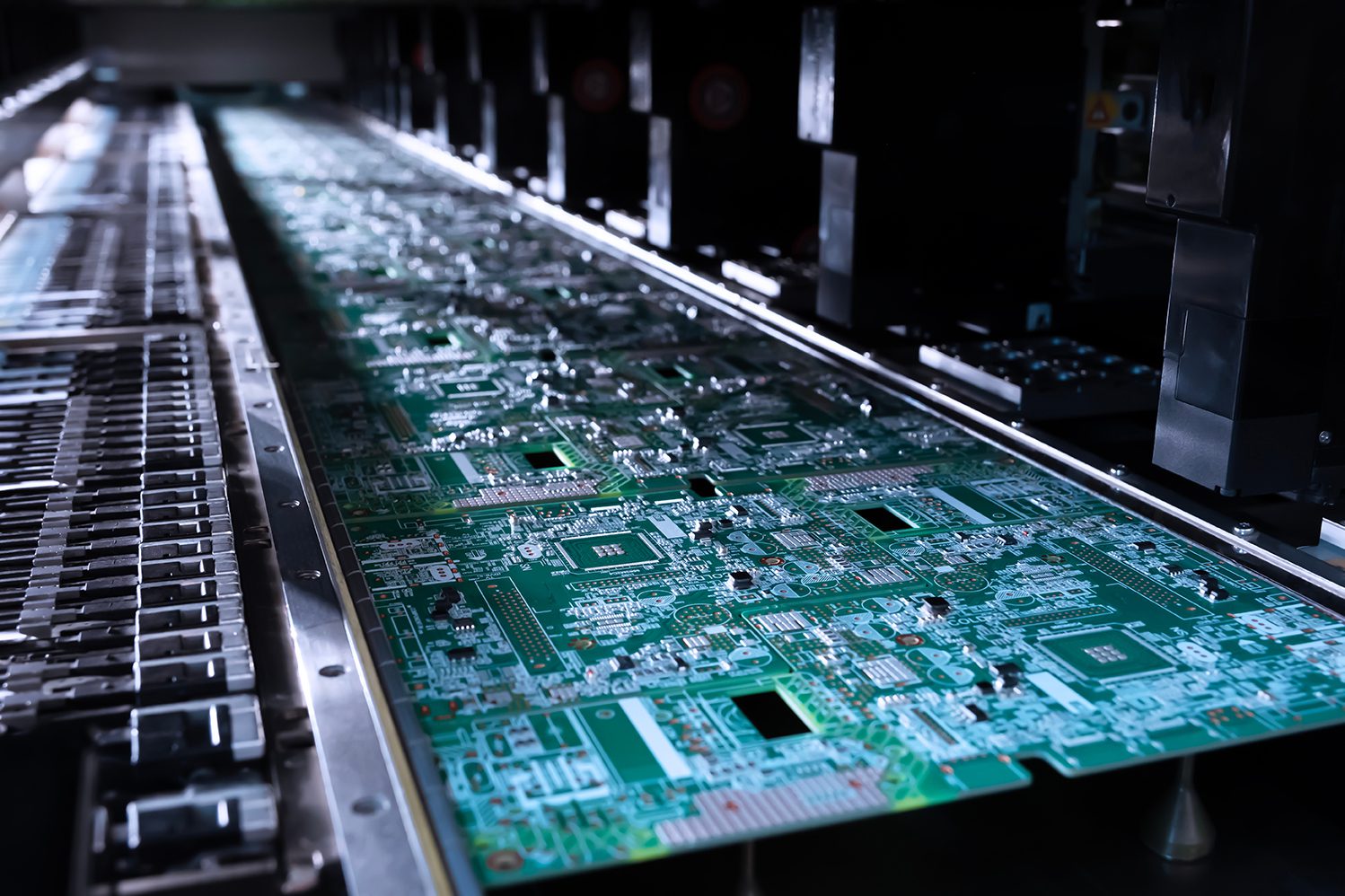

Through-Hole Technology (THT)

While SMT is standard for many modern electronics, MGT Technologies also provides comprehensive Through-Hole Assembly services, essential for applications requiring the mechanical strength and reliability of through-hole components.

- Precision THT Assembly: Inserting component leads through PCB holes with secure soldering for structural stability.

- Mixed Technology Expertise: Offering mixed technology assembly by combining SMT and THT components on the same PCB, supporting complex designs that demand both high-density SMT and robust through-hole components.