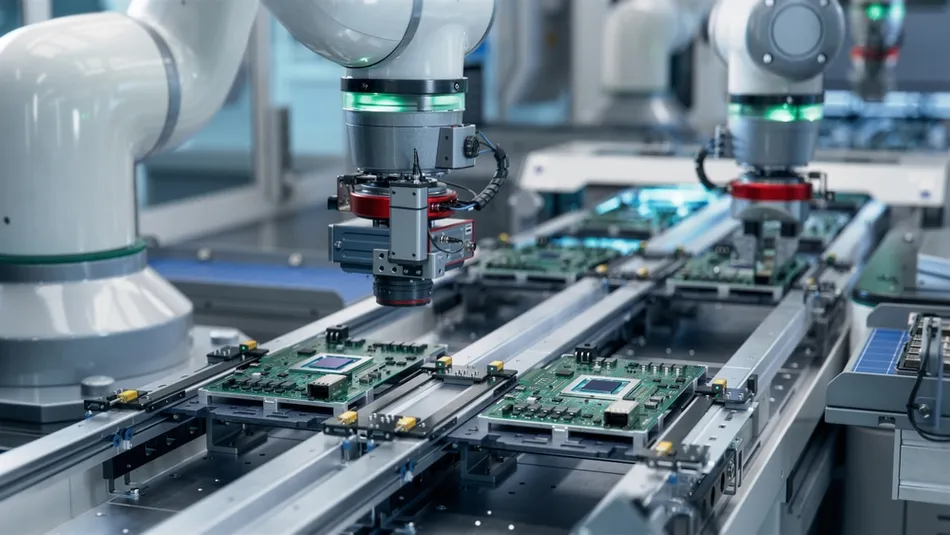

Turnkey Assembly

Turnkey Assembly Solutions: Precision from Taiwan, Scale in Manufacturin

Accelerate Innovation with Precision Machining

Innovate with Confidence

Transform your manufacturing challenges into strategic advantages with MGT Technologies. We are committed to delivering high-quality, fully assembled products, managed with transparency and precision, from the heart of Asia’s manufacturing hub.

MGT Turnkey Assembly Process

MGT Technologies offers a comprehensive, end-to-end approach to bringing your products to market. Our integrated services cover every critical stage:

- Design for Manufacturability (DFM) & Optimization: We collaborate with your engineering teams early in the process to optimize designs for efficient manufacturing, cost-effectiveness, and product reliability. Our Taiwanese engineering expertise ensures designs are robust and ready for scaled production.

- Precision Component Sourcing from Taiwan: We leverage our extensive network of vetted, high-quality Taiwanese manufacturers for all critical components. This includes advanced PCBs, FPCBs, custom metal parts (die casting, extrusion, CNC machining, stamping), plastic injection molded parts, wire harnesses, fasteners, and specialized rubber components.

- Rigorous Quality Assurance & Inspection: Quality is paramount. Our Western-managed team in Taiwan implements stringent quality control protocols at every stage, from raw material inspection and in-process checks to final product verification. This ensures components meet exact specifications before integration.

- Strategic Sub-Assembly in Taiwan: For complex modules or sensitive sub-assemblies requiring specialized precision, we facilitate initial assembly and testing in Taiwan, ensuring the highest standards of quality before shipment.

- Seamless Final Assembly at Scale: We coordinate the transfer of components and sub-assemblies to partner facilities equipped for efficient, high-volume final product assembly. Our team oversees these operations, ensuring adherence to schedules and quality benchmarks.

- Advanced Testing & Validation: Comprehensive functional testing, performance validation, and quality control are conducted on finished products to guarantee they meet all performance requirements and international standards.

- Custom Packaging & Logistics: We design and implement optimized packaging solutions for protection and retail readiness, and manage all logistics, ensuring secure and timely delivery of your finished products to your desired global destinations.